How ColorBase is Fueling Disruptive Change

December 13, 2022 by Marco Roos

It's not unusual for companies to be convinced about their products, strategy, or vision, but we REALLY are - and so are many of our partners. What makes us so sure that we are onto something?

With a strong track record in the large format printing industry over the past 20 years, we are really used to looking at the big picture - and not just in terms of output, but also by spotting trends, changes and challenges faced by all stakeholders in our industry. The COVID pandemic has probably been one of the most disruptive global events we have seen in the past few decades. On top of that, we have also seen that neighboring industries are undergoing rapid transformation, such as industrial printing, and labeling and packaging markets. The trends driving these transformations are the above-mentioned global supply chain crisis, climate change, and companies’ and consumers’ growing awareness that our economic model of unlimited consumption is no longer sustainable.

The printing industry plays an important role in this necessary transformation. We produce packaging, we print textiles, we print magazines, we print decorations and wallpapers, we (re-)style retail stores and we see more and more industrial processes supplemented by digital printing technologies. Our printed materials are now floating in the oceans, lying in landfills, scattered on the Earth’s surface, or simply stored in warehouses around the globe as stock. We as an industry are not always responsible for where these products end up, but we also have not done enough to turn the situation around and find a better way to solve this problem.

We Need the Cooperation of All Parties Involved

Finding a solution to this is not easy. It requires a collaborative effort from manufacturers, suppliers, printers, print buyers, consumers, waste collectors and recyclers. It requires our entire industry to be connected, not only to each other, but also to the print buyers, recyclers, waste collectors and eventually the consumers themselves. Connecting companies isn’t the biggest challenge - a much bigger problem is the fact that most of the information around materials is not standardized, which makes it not only difficult to compare them or find alternatives, but also impossible for recyclers and waste management companies to figure out what they are dealing with. As a result, most of the truly circular products created by printing companies are the result of a tremendous amount of effort from the printing companies themselves, and in most cases they are driven by the explicit demand from the print buyers. It requires a tremendous amount of time and effort - or is simply unaffordable - for most companies to do the research and connect the points between the different steps in the life cycle of a product, resulting in a very limited number of truly sustainable solutions. Telling the world that we have to change our mindset and focus on the ecological impact of our businesses first is cool, but if it is not economically sustainable, the sad fact is that not much will come from it. We need to change something here.

How ColorBase Makes Disruptive Change Possible

We are convinced that we are going to fuel that change. I know that sounds more arrogant than it is convincing, but let me explain why we so firmly believe that:

Over the past twelve years, we, ColorBase, have been building a cloud based profiling solution, which currently serves over 125,000 printing companies, with over one million profiles, 4,000 material specifications and data sets. All the leading manufacturers in the industry are using this solution. Besides that, we have done more: we have put significant time and resources into developing an ISO standard (ISO 22954) which standardizes the way color profiles are selected. It is achieved by submitting a standardized set of data to a remote server. We have also spent several years fine tuning an ontology and data model for print materials, which helps describe materials, their properties, performance, availability, components and any other type of data that might be required to be guided through their entire life cycle, resulting in an ultramodern data structure, AI/ML ready, searchable, open and flexible that allows for all kinds of cool applications and connections. However, the most important reason we are convinced that we are going to pull this off is our incredible network and position in the industry. We have spent 20 years building the trust and relationships with material-, printer- and software manufacturers in more than 100 countries around the world, covering a substantial part of the supply chain in the digital printing industry and we do have the mindset, people, knowledge, experience and reputation to expand that even further into the upcoming markets.

Great, you might think, but how!?

Having been in this unique position for so many years and having established relationships with all major manufacturers, we have introduced them to our 5 year vision and strategy. These are not only big but also logical, and they’re getting connected through a step-by-step approach - together, in close collaboration with major stakeholders in our industry.

- We have built a cloud-native digital pipeline with modern data infrastructure and flexible models, powered by Google Cloud and Vanenburg’s Rappit development platform.

- This digital pipeline enables connections to third-party companies. Imagine manufacturers connecting their ecosystem, printers and software to the pipeline to dynamically update material information, availability and profiles. All of this is powered by three digital printing intelligences and possessed by ColorBase.

- We have developed THREE applications ourselves, which utilize the power of this digital pipeline to the max:

ColorBase Labs - a cloud space that helps manufacturers and print shops to structure their testing and research efforts. It standardizes quality thresholds, testing procedures and formatting of scores and results. It allows the sharing of results and test methods, and also structures data for later use in the pipeline.

ColorBase Exchange - a marketplace for manufacturers and resellers of printing materials. There are dynamic pricing, stock management, reseller management and even smart production planning options to sell production runs before they are started. This marketplace can further reduce waste, optimize production means and enable data driven forecasting.

ColorBase Toolbox - a collection of tools focussed on enabling print shops to print better, more easily, and with greater consistency. It currently offers more than one million profiles downloadable for free, targeted marketing opportunities for manufacturing brands, blogs and much more to come. It’s a great way to collect and distribute data and reach a large audience scale with targeted information.

Our digital pipeline connects to anything digital, from legacy SAP, Dynamics, Oracle to other systems, enabling companies to decentralize their IT infrastructure and to use highly specialized applications through an industry connected ecosystem.

Are We Still a Color Management Company?

Yes, we are! However, we do so much more than that, as you have read. Instead of repeating the same thing over and over again, we aim to digitize our knowledge and the results of our work. Moreover, we want to use it to transform ourselves into a knowledge company that has become scalable by turning its services into digital applications and analytics tools that use data collected through a connected ecosystem in our digital pipeline. To those who have followed us for the past 20 years: keep following us; we are transforming and it is exciting!

Digital transformation in our industry has started on the production floor. With the introduction of digital production methods, workflows, tools and that transformation still has a long way to go in all other printing industries. If we want our industry and our planet to truly take advantage of that transformation, we need to start transforming the way we do business. This requires an agile infrastructure, with instant data and information at all stages of the product’s life phase. From making material production more efficient, speeding up the procurement process, making printing easier and more flexible, to making materials digitally traceable, no matter where they go, a truly sustainable printing industry is coming.

The future is data, standardized, connected and exchangeable data. Join us for the revolution. We need each other's support to create a better place for future generations.

Contact us if you want to know more about what we could do for your organization, or if you believe you could do anything to help us achieve our goals.

Together, for all of us!

Read more articles

Re-board®: Making Sustainable Event and Exhibition Constructions

Source: https://nordwerk.co/ For those seeking environmentally friendly alternatives to conventional materials like MDF/plywood, foams, and plastics in event and…

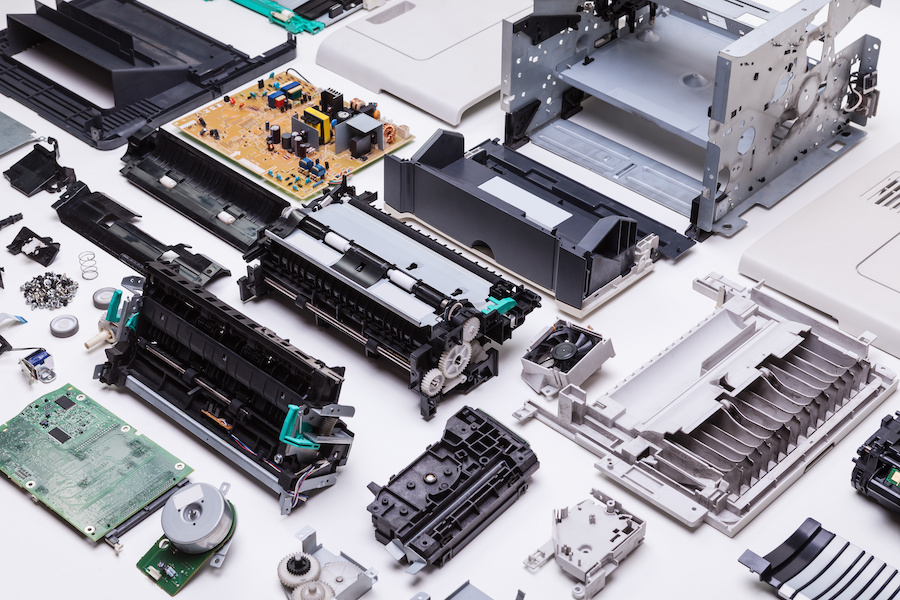

Why Printer Maintenance is Important in Color Management

It was mid-summer in the Midwest. My business partner and I were driving from our home state to an…

ColorBase, Under the Hood: The Data Model Upgrade Enabling a Smarter Printing Industry

Quiet Transformation Our industry’s most advanced database of material, printer, RIP and ICC profile data is undergoing a quiet…